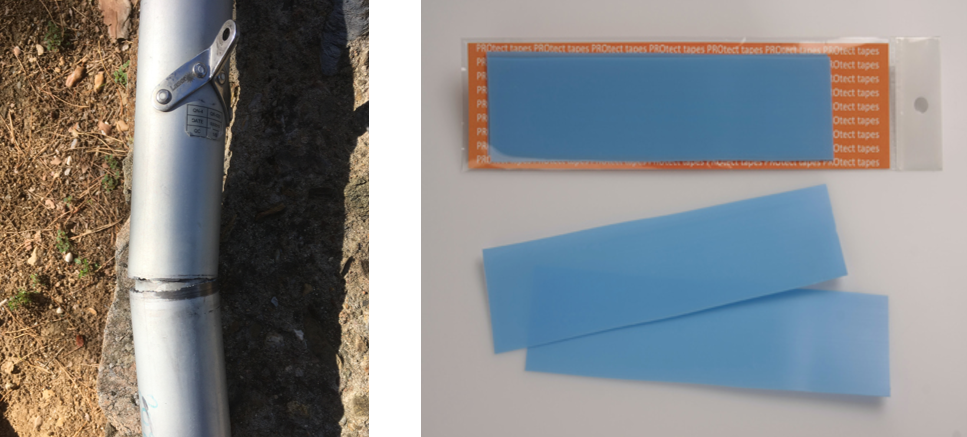

We have just added Mast Wear Protect strips to our increasing range of solutions for your Laser. This was prompted by a failure of my own Radial mast a month ago – the first mast breakage that I had. It was clear to me that the mast had been weakened by wear around the deck level – which is where it broke. Comprising two strips of UHMWPE with acrylic adhesive to be applied around the mast at the bottom and at the deck level, they help reduce the wear and tear of the gelcoat, and abrasion of the anodising on the mast itself. These wear protect strips are class legal (ILCA Rule Part 3, Section 19, Point (i). You can find them listed here Mast Wear Strips

News

Congratulations to Southeast Sailboats sponsored sailors Michael Beckett and Federico Tocchi at the European Senior championships in La Rochelle France – both on the podium!

- May 13, 2019

- 1 min read

Southeast Sailboats Max Hunt finished 2nd GrandMaster and 4th overall out of the 54 starters. Now back in the workshop/office and orders are shipping.

- April 08, 2019

- 1 min read

Southeast Sailboats will be at the London Dinghy Show this weekend. Come and see us on the Marlow Ropes stand G42 on Sunday at 12.30-1.10 where we will be doing some splicing demonstrations, showing how we make our world class rigging for the Laser.

- February 27, 2019

- 1 min read

As a result of customer demand we have added a new configuration of our ever popular 8:1 downhaul system. This version uses Harken 29mm/18mm blocks…..

- February 27, 2019

- 1 min read

We have just added blue/black to our existing range of Marlow Excel Racing GP78 which is proving very popular. Custom made by Marlow for Southeast Sailboats this additional colour gives you more options….

- February 26, 2019

- 1 min read

Look around the dinghy park at a major Laser event will show you that even at the highest level there is no ‘right way’ to rig your control lines. Much of how we rig our Laser is down to what we are comfortable with, maybe we just haven’t changed what seems to work, or perhaps we don’t think that good rigging matters – but it does.

Good control systems are important as it takes one more variable out of your racing: good controls are strong, well built, they allow you to trim your sail correctly even when you are tired, and they are always rigged the same – all of which provide psychological and mechanical advantages.

No matter how you rig your Laser, in a world of marginal gains, good rigging can make a difference by reducing risk of failure, maximizing ease of use and consistency.

So, what can be done? Your rigging should be easy to fit in the same way from event to event, so that nothing changes and your calibration remains consistent. It should also be secure – barely a major event goes by without seeing someone suffer rigging failure. The third objective is to ensure our controls are easy to use by making them as effective and efficient as possible by choosing the right blocks, ropes, appropriate purchase and rope types for each system.

Splicing v knots – Avoid tying and untying knots by having some of your lines and blocks spliced. Splicing, providing it is done properly, can give you both consistency and increased security. The current generation of blocks such as Harken’s carbo-blocks are designed to be ‘soft attached’ using Dyneema® or similar line, but tying them on incorrectly can result in the block being pulled apart at the head. This is particularly critical for the highly loaded kicker centre block. A good solution is to Brummel (lock) splice them in the right position in the first place.

Blocks: Larger sheave sizes up to the maximum 30mm allowed under class rules, increase efficiency as a result of the larger radius that the rope travels around, and can make a real difference particularly on the highly loaded cunningham. Here, blocks such as Harken’s 29mm T2 Soft-Attach Carbo blocks are ideal. For the lighter loaded outhaul 18/20mm blocks work fine.

Purchase: Increasing purchase is most appropriate for the cunningham when using the heavier MKII standard sail, and as the range of travel on the new sail is smaller, it reduces the 8:1 downside of more rope in the cockpit.

Radial and 4.7 sailors are also switching to an 8:1 downhaul with a caribiner at the top of the kicker base to attach the primary to. The 8:1 makes it much easier to get maximum downhaul on, and if conditions change whilst sailing, the caribiner allows the sailor to reconfigure the downhaul primary on the water, so that entire system is then able to run down one side of the boom, maximizing the range of travel.

Effective, efficient systems reduce the effort you need to put into changing your settings, making accurate adjustments faster and easier, especially when you are tired.

Southeast Sailboats fully spliced 8:1 cunningham is specially designed for the MKII standard sail. The tandem block primary assembly is spliced from a single length of Dyneema. The lower block assembly is passed through the loop on the primary and then under the kicker tang to fix it all in place. No knots to tie or come undone, no shackles or pins to undo. Effective, efficient, consistent, secure.

Whist some systems require maximum purchase, some sailors have been reducing purchase on the kicker from 15:1 to 12:1. Better running blocks with better rope all help the efficiency of the system and the ability to pull on the kicker quicker and with less rope.

Releasing the outhaul is something that can be frustrating in light winds. Normal outhaul systems traditionally use a shock cord (bungee) that runs from the boom centre cleat, to the sail clew, and sometimes back to the boom cleat. This type of system does one thing – it tries to pull the sail inboard. A far better system is one that pulls the sail inboard, and, at the same time pulls the control line back through the cleat, fairlead and blocks. This is what Team GBR sailor Michael Beckett has to say on the subject….

“What makes this so effective is that for every inch of outhaul you pull on, it stretches the elastic by about an inch and a half, so the tension increases exponentially. The outhaul is easier to pull on and will release more effectively. The only tricky part about this is that you have to attach the outhaul primary, secondary and bungee ends all onto one small 18mm block. I have been really impressed by the solution Southeast Sailboats produced to solve this – a small toggle spliced into the primary line that the end of bungee loops over. All in all it is a smart solution to make sailing a Laser that little bit more satisfying, enjoyable and effective”

Rope: There are a lot of performance criteria in rope selection but for Laser control lines the most important is minimal stretch under load so that settings remain unchanged, whilst being strong, durable, low in friction and friendly on the hands.

Slippery Dyneema® SK78 D12 is the default choice for primary lines. The cunningham primary must do a 180 through the tack cringle/grommet and minimizing friction is important as pulling the cunningham on is hard enough. The cunningham primary line diameter is a compromise between having a thin line that risks getting trapped in the gooseneck, or thicker line and greater friction. The outhaul primary also has to do a 180 through the boom end eye but with a lighter load than the cunningham and a larger bend radius.

Secondary lines should be ‘hands friendly’ both in terms of diameter and grip. Secondary lines are also the ones that usually fail, with the cover giving way leaving just the Dyneema® core. Ropes do wear out, and should be inspected for signs of wear, particularly for the highly loaded kicker and cunningham where the cleat abrades the cover, and for the cunningham where the secondary line may also snag on the kicker clevis pin.

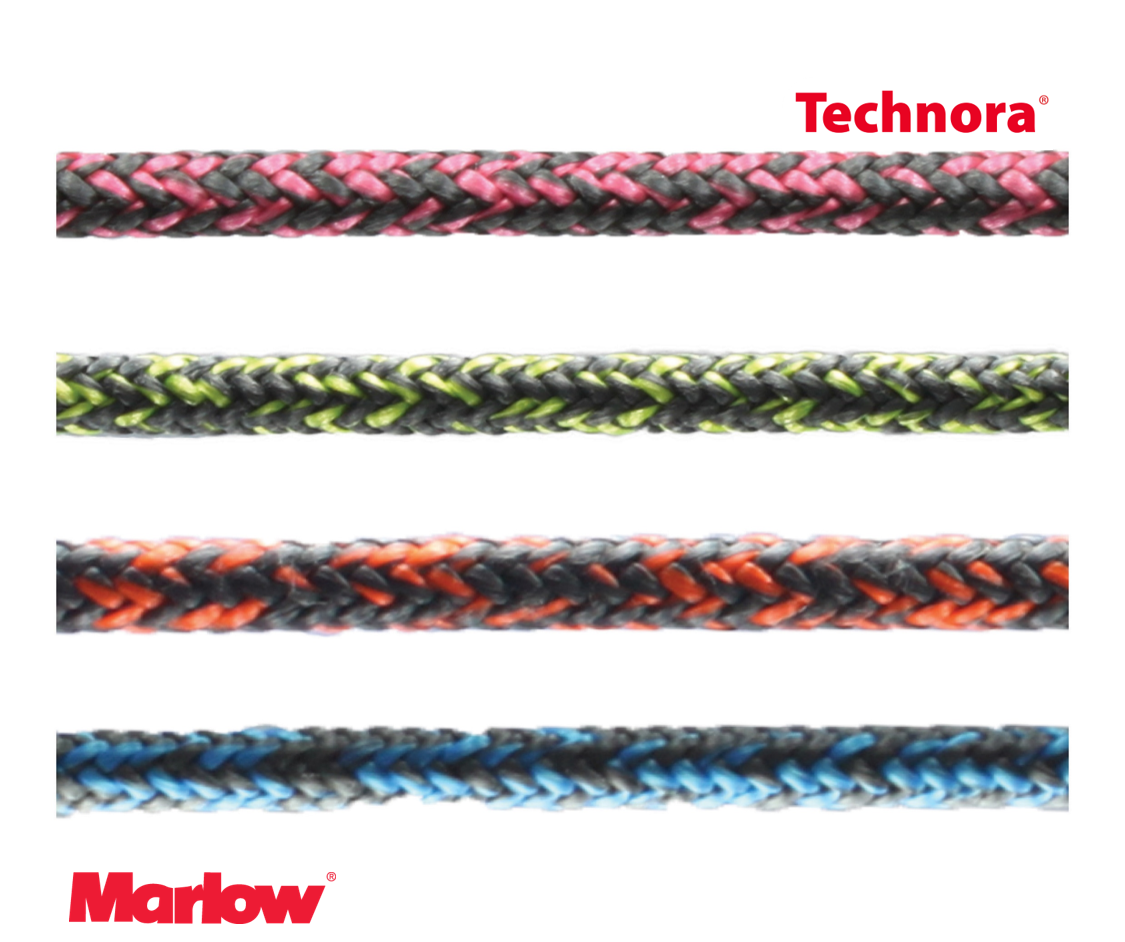

The recent rule change removing the restriction on Aramid fibres, lines with Technora® in the cover can now be used for all three control lines. Technora® provide greater durability and grip than lines that are just Polyester covered, but can be ‘stiffer’ that normal 4mm secondary lines. So, maybe for the first time, it is worth considering using different rope types for each system. Whilst Technora® covered ropes such as Marlow’s Excel Racing GP78 work great on the highly loaded kicker and cunningham, it is worth considering more supple lines such as the fractionally thinner Robline Dinghy Polytech for the lighter loaded outhaul if you want to have to avoid ‘helping’ the outhaul off when you uncleat it!

Colours: Good colour usage on secondary lines is vital, ensuring that you can quickly distinguish and instantly grab the correct control line. Rope lengths should also be set ‘just right’ to minimize excess line in the cockpit, and so you can use the handle to maximum effect.

With everything set up perfectly you can minimize mistakes and tangles and maximize the consistency, effectiveness and security of your controls.

Last but not least … little things like frayed rope ends, outer covers that are separating from their cores, knots to try and tie in a consistent place, can all result in lost time rigging, frustration, when we should be concentrating on what is important. Having our rigging clean with spliced lines, and properly stitched or sealed rope ends can help eliminate this source of psychological disadvantage.

The top mainsheet core is starting to pull out of the cover making rigging frustrating. Worse still if the cover is pulling off and your stopper knot doesn’t hold the core. The lower mainsheet end has been stitched with Dyneema and covered with heat shrink sleeving secured with epoxy adhesive.

Summary – good rigging matters! In competitive situations where marginal gains are important, just like having straight spars, aligned foils, a polished hull and a good sail, having a well rigged Laser means that you haven’t left that element to chance.

This is an updated version of an article first published in November 2016 by Max Hunt. A regular at the Laser Masters worlds and championships across Europe, Max Hunt runs Southeast Sailboats – a small business that provides custom made rigging solutions for the Laser dinghy – www.southeastsailboats.co.uk

See our unique control line systems on a Laser on the RYA stand at the 2019 RYA Dinghy Show in London. Southeast Sailboats will also doing a splicing demonstration on Sunday – find us on the Marlow Ropes stand.

Share page

- February 20, 2019

- 6 min read

We have just added Robline Dinghy Polytech to our range of lines. With a blended Technora/Polyester cover for excellent durability and grip, and a Dyneema SK78 core. This is our premium ‘thin’ control line which we recommend for use on the outhaul as it runs extremely well through the smaller 18/20mm blocks when under lighter load, making it easier for the outhaul to release when uncleated. The Technora in the cover provides greater longevity and excellent grip in the hands. Available from stock in blue, lime and orange.

- February 04, 2019

- 1 min read

NEWS! Technora based control lines – class legal from 1 January 2019 and now available for all our systems.

In late 2017, Southeast Sailboats submitted a rule change proposal to ILCA to remove the Laser class restriction on Aramid fibres for the kicker/vang and cunningham. The rule change, voted on during 2018, has just been released by ILCA enabling Southeast Sailboats to sell class legal control line systems using harder wearing Technora® control lines that are made with aramid fibre.

Throughout 2018 we assessed numerous control lines containing Technora® and have selected Marlow Excel Racing GP78 as our premium control line. This hard wearing 4mm control line has a blended Technora®/Polyester cover and a Dyneema® SK78 core. The Technora® in the cover provides greater longevity especially for the highly loaded downhaul and kicker/vang where the cleats cause wear, and excellent grip in the hands. Available from stock in orange/black, lime/black and pink/black as a system option for our world class control line systems, or as rope by the metre. We also offer a re-roping service if you have bought systems from us in the past that you would like to upgrade.

- December 28, 2018

- 1 min read